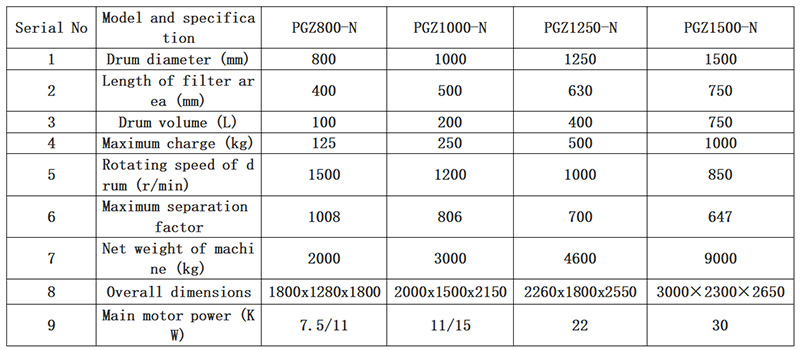

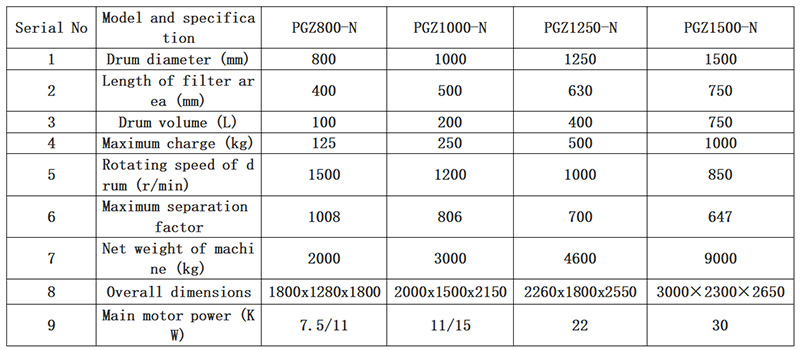

Pharmaceutical vertical automatic scraper bottom discharge centrifuge PGZ800 PGZ1000 PGZ1250 PGZ1500 PGZ1600

The GMP standard clean centrifuge in the pharmaceutical industry is a kind of high efficiency separation equipment,which is produced in accordance with the Order No.9 of the State Drug Administration,"Good Manufacturing Practice"(revised in 1998),and the National Drug Administration,"Good Manufacturing Practice"(revised in 1998).The main improvements are:

Centrifuge is specially designed and manufactured according to GMP standards of pharmaceutical enterprises to ensure pollution-free and thorough cleaning of separation space;The equipment structure has no pollution dust,no cleaning dead angle design,and multiple CIP cleaning system in the enclosure is realized.Ensure that the surface roughness Ra of all surfaces in contact with materials is≤0.8 um.

All exposed parts shall be lined with stainless steel and polished with surface roughness Ra=0.8 um

All seals are PTFE seals,which can meet the requirements of airtight explosion-proof and nitrogen filling.

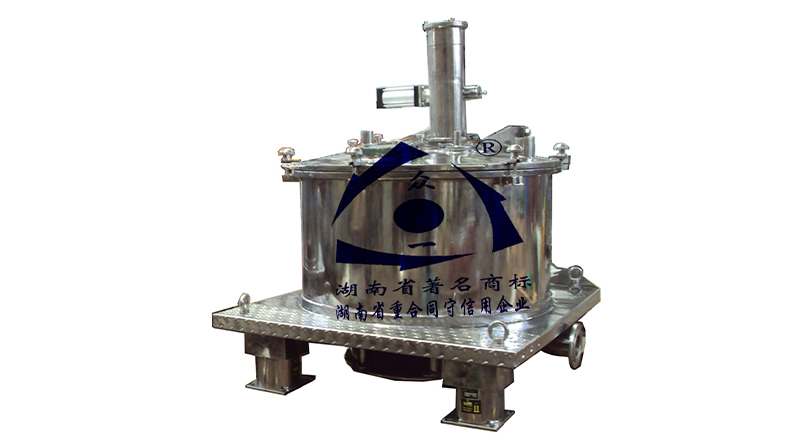

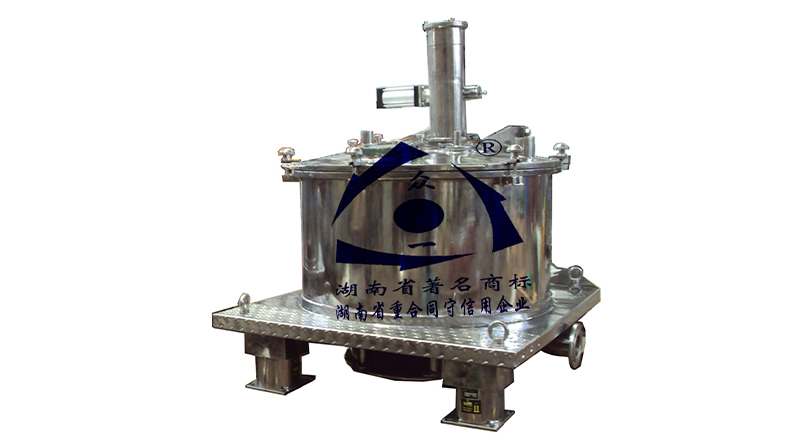

PGZ flat plate automatic lower discharge centrifuge is a high-performance centrifugal filtering device for intermittent operation of lower discharge.It is applicable to the solid-liquid separation of suspensions with high solid-phase dispersion,moderate particle size,need to be washed,and low liquid viscosity.It is not only suitable for the separation of small batches of multi varieties of materials,but also suitable for mass production.It is widely used in medicine,chemical industry,light industry,food,national defense and other industrial fields.

The product has no foundation installation,cancels the traditional hanging column base,simplifies the installation process,has simple structure,beautiful appearance,and is convenient for cleaning and disinfection;The absorption type isolator is adopted,which has no vibration interference to the foundation ground and surrounding equipment;The surfaces of all elements in contact with materials are corrosion resistant stainless steel;High efficiency washing nozzle shall be selected for washing,and there shall be no blind area when washing fully.

It is driven by frequency converter and equipped with PLC programmable controller to realize soft start,stepless speed regulation,electric feedback braking and on-site speed regulation of the centrifuge.It is equipped with cover opening protection,filter cake thickness detection in the drum(material controller),vibration switch protection and speed monitoring.The whole process of feeding,washing,dehydration and unloading of the centrifuge is fully automatic.

The centrifuge is controlled in two places,and the operation box is set on site.

The upper cover of the centrifuge is a quick opening type.The opening and closing are driven by air pressure,which can avoid the impact of oil pollution on environmental health.