brief introduction

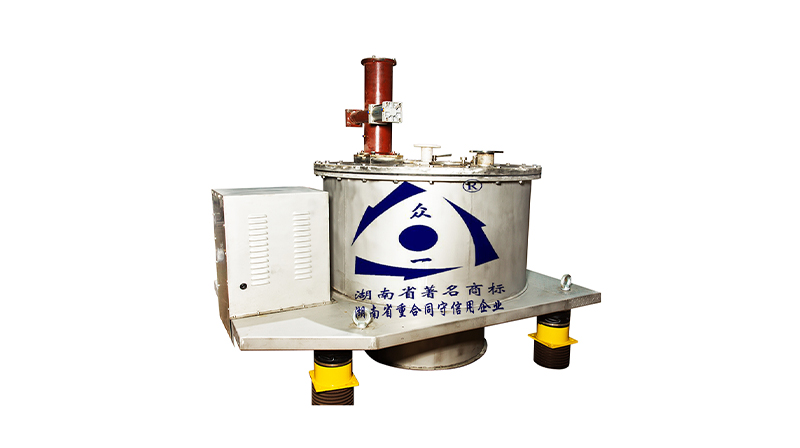

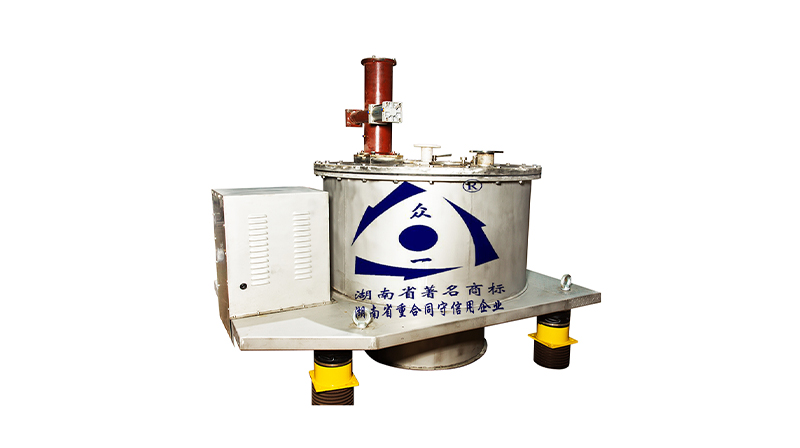

PGZ flat plate automatic lower discharge centrifuge is a high-performance centrifugal filtering device for intermittent operation of lower discharge.The product is installed without foundation,cancels the traditional hanging column base,simplifies the installation process,has simple structure,beautiful appearance,and is convenient for cleaning and disinfection;The absorption type isolator is adopted,which has no vibration interference to the foundation ground and surrounding equipment;The surfaces of all elements in contact with materials are corrosion resistant stainless steel;High efficiency washing nozzle is selected for washing,and there is no blind area when washing fully.At the same time,GMP compliant products can be made for pharmaceutical and food industries.

application

It is suitable for separating suspensions containing solids with a particle size greater than 0.05mm.It is suitable for solid and liquid separation of suspensions with high solid dispersion,moderate particle size,need to be washed,and low liquid viscosity.It is not only suitable for the separation of small batches of materials with many varieties,but also for mass production.It is widely used in medicine,chemical industry,light industry,food,national defense and other industrial fields.

characteristic

It is driven by frequency converter and equipped with PLC programmable controller to realize soft start,stepless speed regulation,electric feedback braking and on-site speed regulation of the centrifuge.It is equipped with cover opening protection,filter cake thickness detection in the drum(material controller),vibration switch protection and speed monitoring.The whole process of feeding,washing,dehydration and unloading of the centrifuge is fully automatic.

The centrifuge is controlled in two places,and the operation box is set on site.

The upper cover of the centrifuge is a quick opening type.The opening and closing are driven by air pressure,which can avoid the impact of oil pollution on environmental health.

working principle

The motor drives the drum to rotate.At the feeding speed,the material is introduced into the drum through the feeding pipe.When the feed reaches the predetermined volume,stop feeding and rise to high speed separation.At this time,washing can be carried out.In the process of feeding and high-speed separation,under the action of centrifugal force,the liquid phase substances pass through the filter cloth and the filter hole on the drum wall and are discharged from the drum through the liquid discharge pipe.The solid phase substances are trapped in the drum.After the separation,the speed changes to the unloading speed.The scraper automatically lifts,rotates and reciprocates to scrape the solid phase substances off the drum wall and discharge them from the lower part of the centrifuge.

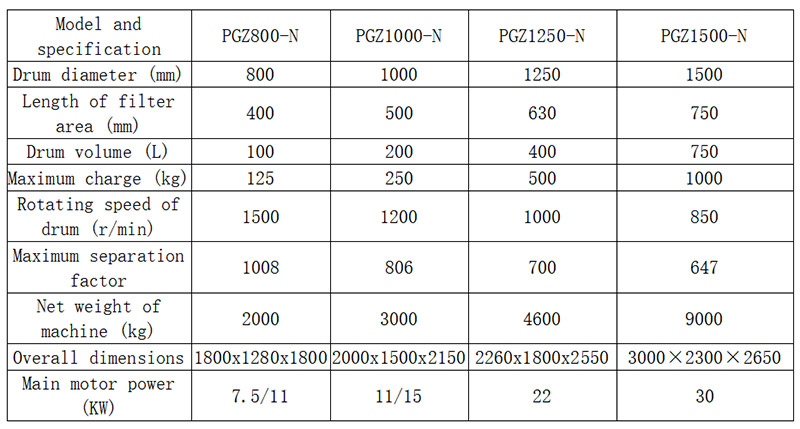

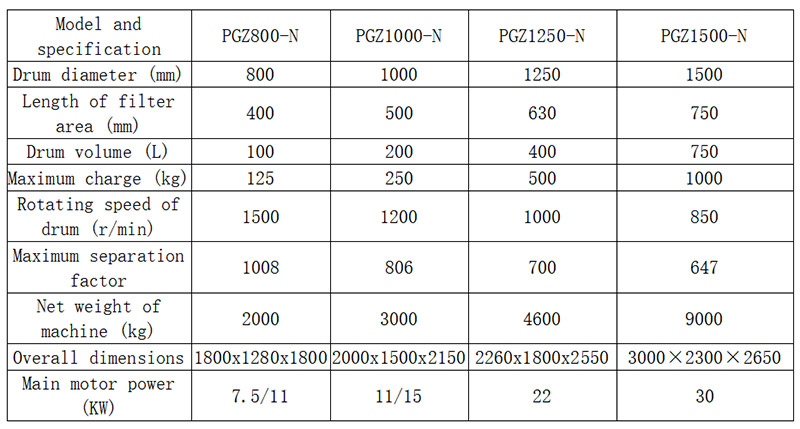

Main technical parameters: