GKH

Horizontal Rotary Siphon Peeler Centrifuge

Product introduction

The product refers to one type of rotary siphon peeler centrifuge redesigned,based on horizontal rotary siphon peeler centrifuge,in response to the characteristics and requirements of application in pharmaceutical and food industry and in accordance with Good Manufacturing Practice(GMP)and is horizontal filtering centrifuge with clearance discharge.With driving forces for filtering including siphon suction similar to vacuum(besides centrifugal force),the filtering centrifuge enjoys higher production capacity and better separation washing effect,compared with common peeler centrifuge.

The centrifuge’s processes such as feeding,washing,drying and rinsing screen are completed at the working speed of the centrifuge.

Application

Besides the applications in sodium bicarbonate separation and washing and dehydration,the centrifuge is also applied to the separation,washing and dehydration of other materials especially those found difficult in separation with small solid particle size such as starch and calcium phosphate while such materials as sodium bicarbonate and saleratus can greatly improve operation conditions.

Characteristics

Its production capacity is 50%higher than that of common peeler centrifuge of the same kind and it can enable lower humidity content in solid products.

Filtering speed can be randomly adjusted to make materials well-distributed in filter medium and thus greatly mitigate vibration and noise.

Operations are under automatic hydraulic control and hydraulic system is well designed and operations are stable and reliable.

Electric control is effected by advanced programmable controller(PLC)with accurate and reliable actions and small volume and long service life,which is easy for adjustments and maintenance.

Multiple interlocking control devices are designed to further enhance the safety of the centrifuge.

Rubber vibration-damping base is designed to substantially reduce harm caused by the centrifuge’s vibration to plant and equipment.

Working Principle

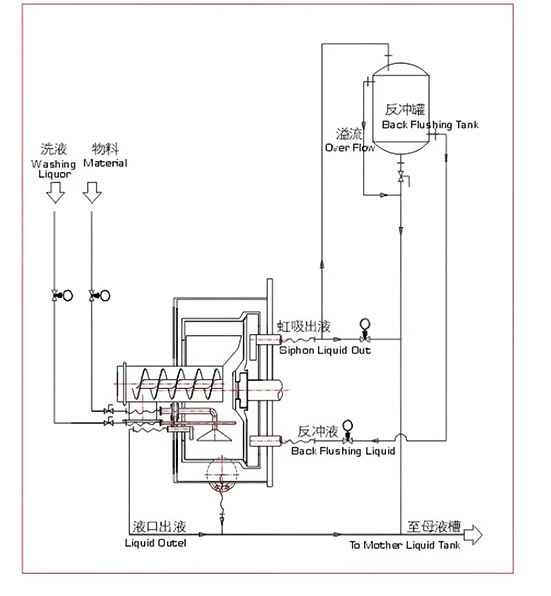

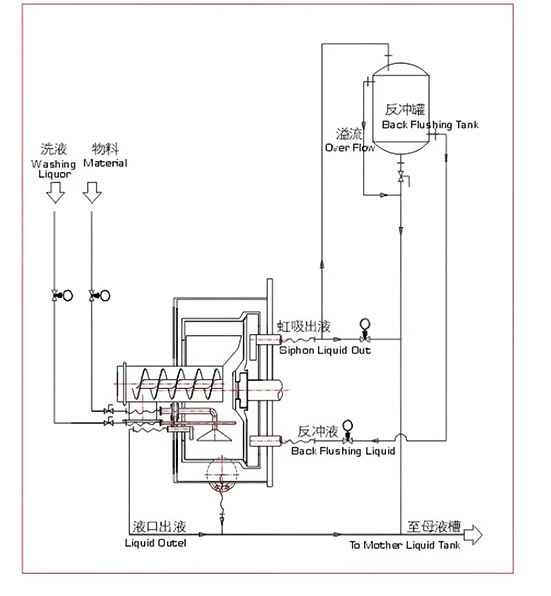

The main motor drives the inner and outer basket of the package to rotate at full speed.The materials are introduced into the basket through the feed pipe.Under the centrifugal force,the liquid phase substances pass through the filter cloth and the filter hole on the wall of the inner basket and discharge from the inner basket.They are collected into the gap between the inner and outer basket,pass through the through hole of the siphon chamber and enter the siphon chamber,and then are pumped out of the machine by the siphon device.

The main motor drives the inner and outer basket of the package to rotate at full speed.The materials are introduced into the basket through the feed pipe.Under the centrifugal force,the liquid phase substances pass through the filter cloth and the filter hole on the wall of the inner basket and discharge from the inner basket.They are collected into the gap between the inner and outer basket,pass through the through hole of the siphon chamber and enter the siphon chamber,and then are pumped out of the machine by the siphon device.

The solid phase is trapped in the inner basket to form an annular filter cake layer.When the feed reaches the predetermined volume,stop feeding,further separate,and then wash.

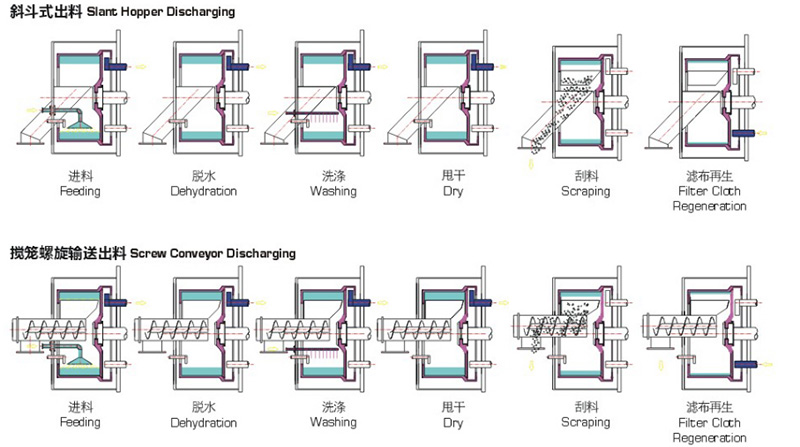

After washing and separation,the scraper automatically rotates to scrape the solid phase out of the machine through the feeding screw,and then automatically wash the screen to start the next.

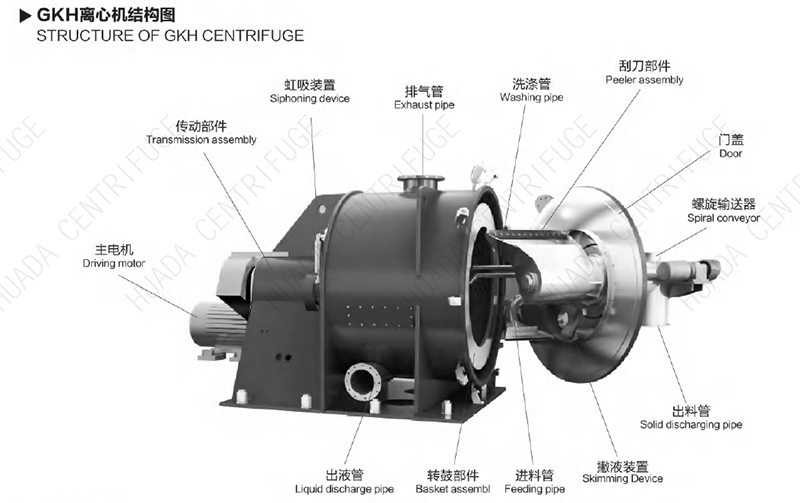

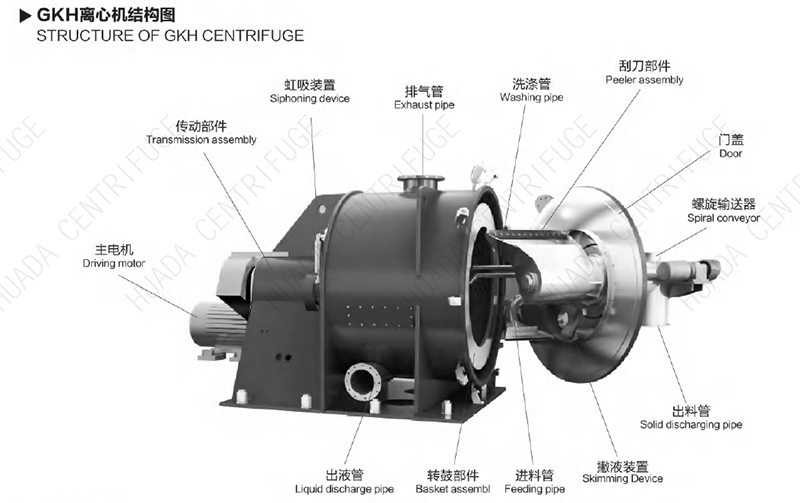

Structure

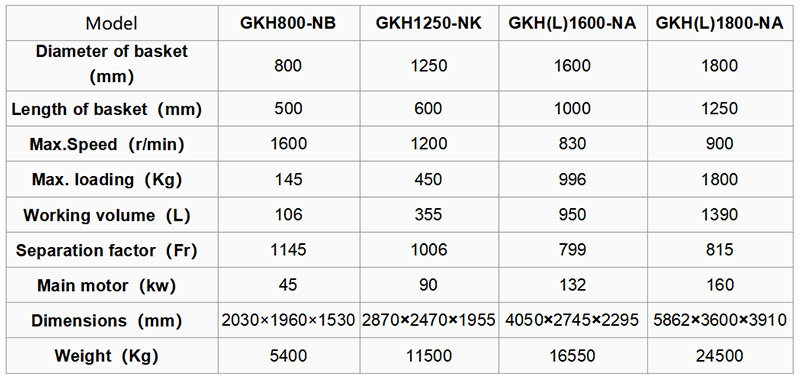

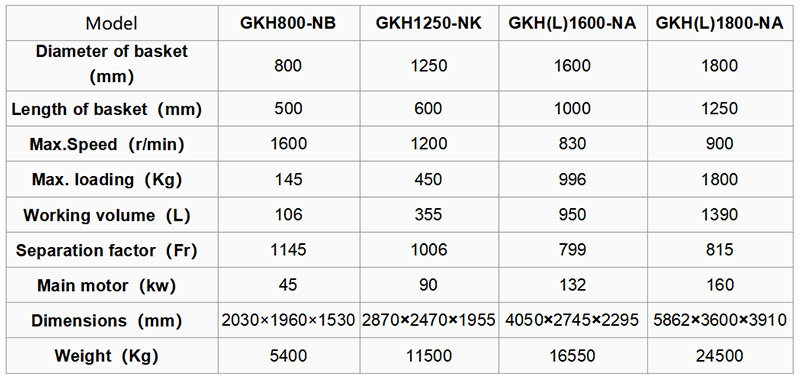

Technical Parameters

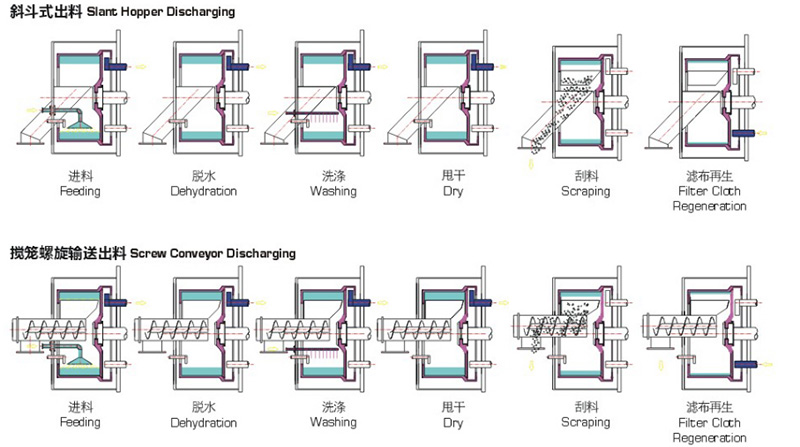

Discharging type

The main motor drives the inner and outer basket of the package to rotate at full speed.The materials are introduced into the basket through the feed pipe.Under the centrifugal force,the liquid phase substances pass through the filter cloth and the filter hole on the wall of the inner basket and discharge from the inner basket.They are collected into the gap between the inner and outer basket,pass through the through hole of the siphon chamber and enter the siphon chamber,and then are pumped out of the machine by the siphon device.

The main motor drives the inner and outer basket of the package to rotate at full speed.The materials are introduced into the basket through the feed pipe.Under the centrifugal force,the liquid phase substances pass through the filter cloth and the filter hole on the wall of the inner basket and discharge from the inner basket.They are collected into the gap between the inner and outer basket,pass through the through hole of the siphon chamber and enter the siphon chamber,and then are pumped out of the machine by the siphon device.