GK

Horizontal Rotary Peeler Centrifuge

Product introduction

Horizontal Rotary peeler centrifuge(Horizontal scraper discharge centrifuge)is a filter centrifuge with automatic operation of scraper discharge.On this machine,it can automatically or manually feed,separate,wash,discharge,and wash the screen.Each process of the machine is carried out at full speed.

The machine adopts an electric hydraulic joint control system with independent electric control system and hydraulic system.During automatic operation,the operation time of each process of the machine is controlled by the electrical control system and can be adjusted within a certain time range.

Application

This machine is suitable for the separation of suspensions with solid phase size of 0.05~1mm and solid phase concentration of 10~80%(weight concentration).Due to the high rotating speed of the machine,the separation factor is high,the separation effect of the machine is good,and the solid phase can be effectively

washed.Therefore,the solid phase humidity obtained by separation is low.Under the condition of reasonable selection and use of filter media,the machine has high production capacity.

Characteristics

The operation of the machine is controlled by hydraulic pressure,with high automation and stable and reliable operation

The electrical system adopts advanced programmable controller,with accurate and reliable control action,small size,convenient adjustment and maintenance,high efficiency and long service life

The rubber damper is designed to greatly reduce the harm to the plant and equipment when the machine vibrates

This machine uses fluid coupling or frequency converter to control the speed transmission of the main motor,so it is not necessary to replace the friction plate as frequently as the friction centrifugal clutch

The machine is equipped with a material layer controller,and the user can adjust and control the thickness of separated materials in the drum according to the use requirements

Working Principle

The main motor drives the basket to rotate at full speed,and the material is introduced from the feed pipe.Under the action of centrifugal force,the liquid substances pass through the filter screen and the filter hole on the basket wall and are discharged from the basket,and are discharged out of the machine through the liquid discharge pipe.The solid substances are trapped in the basket,forming an annular filter cake layer.When the feed reaches the predetermined volume,stop feeding,further separate,and wash at the same time.After washing and separation,the scraper automatically rotates to scrape the solid substances out of the machine through the hopper,and then automatically wash the screen to start the next cycle.

Structure

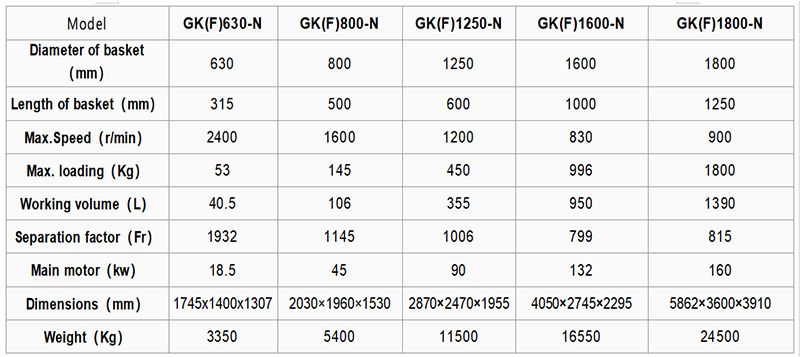

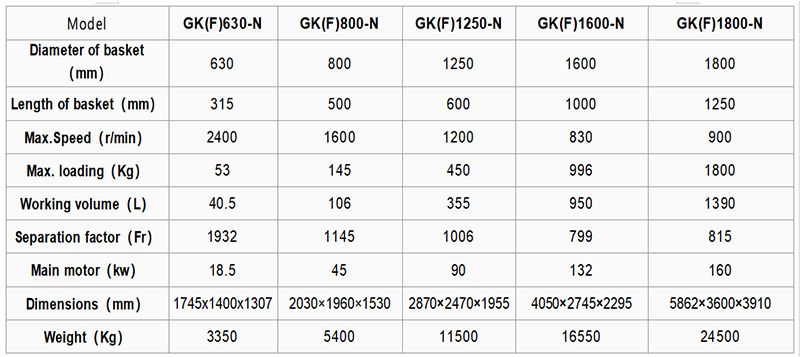

Technical Parameters