- Consulting:+86 131 7042 6166

- Mobile

- WeChat

- CN

HY(WH)

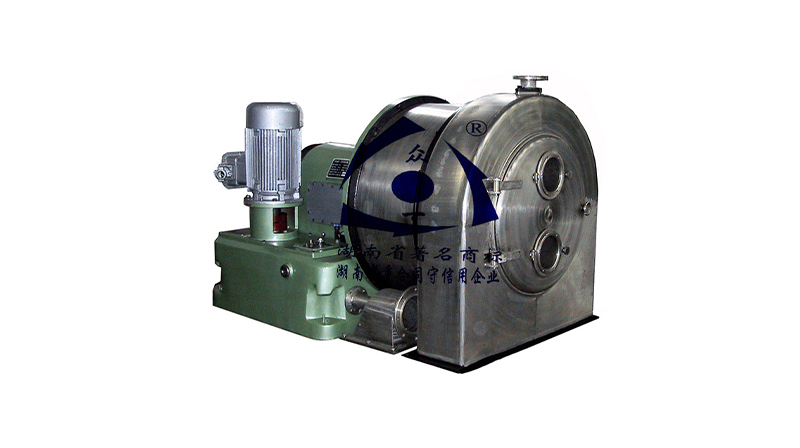

Single Stage Pusher Centrifuge HY800-N/WH800-N cotton seed and nitrocellulose special centrifuge

Product introduction

HY800-N/WH800A centrifuge is a continuous and high-efficiency separation equipment redesigned and manufactured according to national standards such as GB7779-2005 method for preparing centrifuge models and JB/t447-2004 technical conditions for piston pushing centrifuges,based on the old WH-800 horizontal piston pushing centrifuges,in order to meet the requirements of users for the continuous improvement of centrifuge processing capacity and separation effect.The output is increased from about 5 t/h of WH-800 to about 8 T/h,the water content of filter residue is reduced from 5%to less than 3.5%,and the energy consumption is reduced from 4°C/T to 2°C/T.This machine has the advantages of large processing capacity, less power consumption per unit output, less damage to solid particles and small floor area. All parts in contact with materials are made of 1Cr18Ni9Ti stainless steel. It is suitable for processing ammonium bicarbonate, ammonium sulfate, mirabilite, salt, urea and other materials. It is also a special centrifuge for cotton seeds and nitrocellulose. It is widely used in chemical fertilizer, chemical industry, salt production and other departments, but it is not suitable for separating materials containing chloride ions.

Application

This machine has the advantages of large processing capacity,low power consumption per unit output,small damage to solid particles and small floor area.All parts in contact with materials are made of 1Cr18Ni9Ti stainless steel.It is suitable for processing ammonium bicarbonate,ammonium sulfate,mirabilite,salt,urea and other materials.It is also a special centrifuge for cotton seeds and nitrocellulose.It is widely used in chemical fertilizer,chemical industry,salt making and other departments,but not suitable for separating materials containing chloride ions.

HY800-N/WH-800A type centrifuge is a filter centrifuge with continuous operation and hydraulic pulsation discharge.It carries out all operation procedures under full speed operation,such as feeding,separation,washing,drying and unloading.The separated filter cake is discharged intermittently from the middle of the drum(about 30~120 times per minute).The basket of the horizontal piston pushing centrifuge is located at the end of the main shaft,and the inner cylindrical surface is equipped with a filter screen.The pusher inside the basket also performs axial reciprocating motion,which is driven by hydraulic pressure.

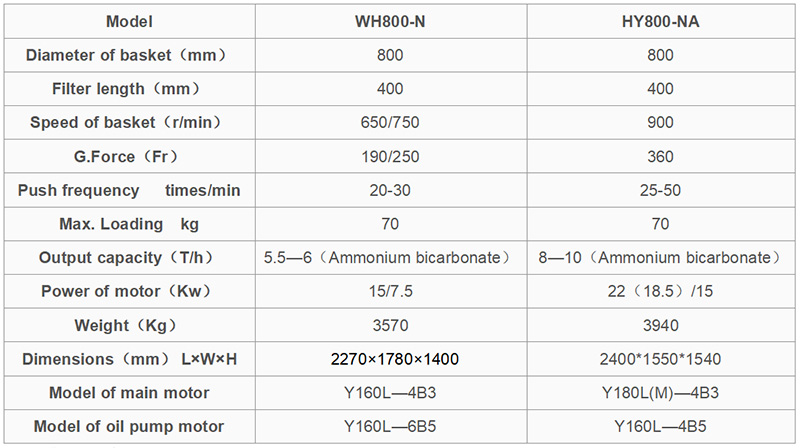

Technical Parameters