HS

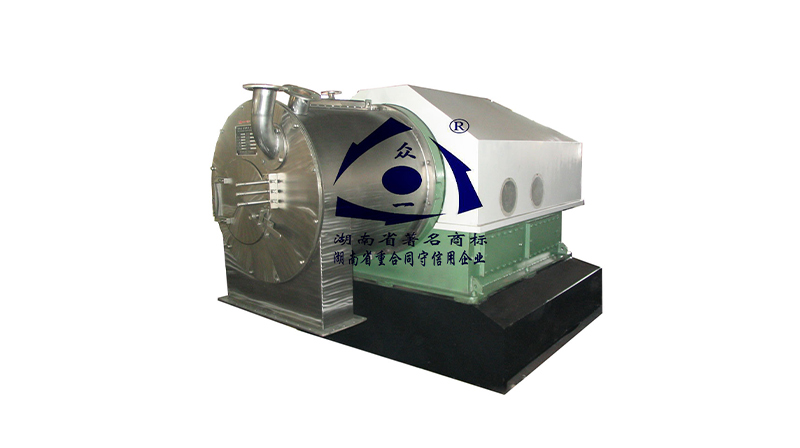

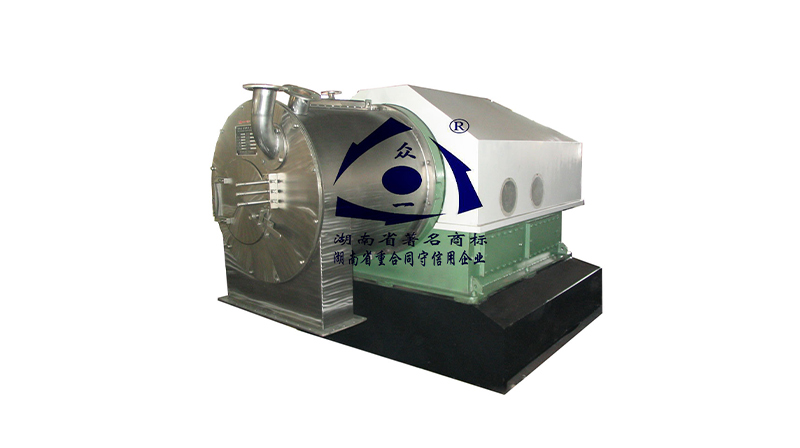

Three-stage Pusher Centrifuge

Product introduction

The three-stage piston pusher centrifuge is a piston pusher centrifuge with three rotating drums,which is based on the two-stage piston pusher centrifuge and further improved to meet the separation requirements of some materials.

The three-stage piston pusher centrifuge has the advantages of large effective drum length,thin filter cake layer,fast dehydration,adequate washing,separation of thinner or thicker suspension,stable mechanical operation,and treatment of fragile crystals and non pressure resistant materials.

The three-stage piston pusher centrifuge has the characteristics of minimum maintenance and high availability.They can filter products effectively,dehydrate quickly,and add multiple washing modes.

Application

The three-stage piston pusher centrifuge can be used in the process conditions where the two-stage piston pusher centrifuge can not meet the separation requirements,such as low feed concentration,high slurry viscosity,high washing requirements,strict requirements for product moisture content,Ruhengfa concentration and crystallization,glucose separation,etc.

The three-stage piston pusher centrifuge is widely used in heavy alkali,glucose,borax/boric acid,soda,sodium chlorate,sodium chloride,sodium sulfate,ammonium chloride,potassium phosphate,potassium chlorate,plastics,bisphenol A adipate,trichlorocyanulamine,p-xylene,polyformaldehyde,lysine,sodium hydrogen phosphate,carbonate,etc.

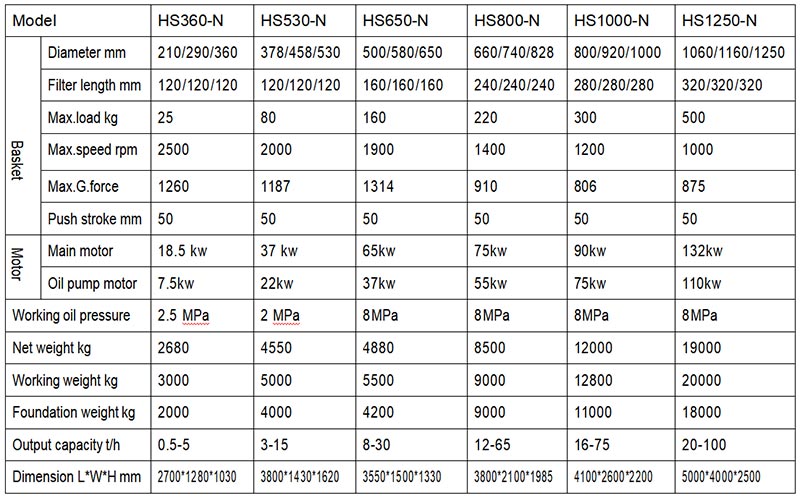

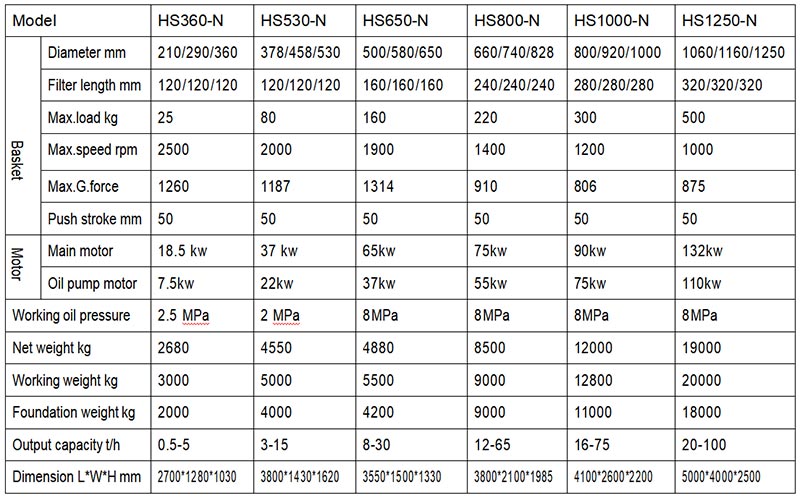

Technical Parameters