- Consulting:+86 131 7042 6166

- Mobile

- WeChat

- CN

HR

Double-stage Pusher Centrifuge

Application

Widely used in chemical industry,chemical fertilizer,salt,alkali,pharmaceutical,food,light industry and other industries.

Typical application materials include:sodium chloride,potassium chloride,ammonium chloride,potassium sulfate,sodium sulfate,mirabilite,ammonium sulfate,potassium carbonate,sodium hydroxide,nitrocellulose,cellulose acetate,potassium dihydrogen phosphate,urotropine,and other sulfates,carbonates,nitrates,phosphates,etc.

Working principle

Working principle

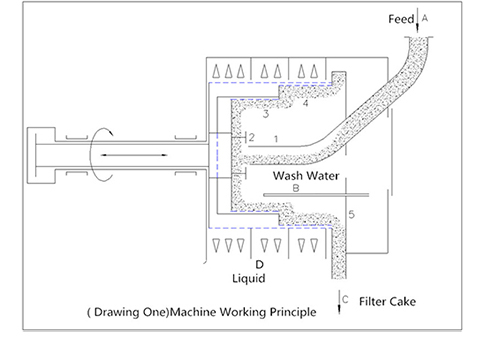

After the basket is rotating at full speed,the suspension liquid to be separated is fed into the feeding pipe 1 and continuously sent to the distributor 2.Under the action of centrifugal force,the suspension liquid evenly distributed on the first stage basket screen 3,and most.of liquid phase goes through out the screen mesh and the hole of basket,while the solid phase in the form of annular filter cake stays on the screen,when the first stage basket returns and pushes the filter cake moving forward a distance along the basket axial,and when the first stage basket process,the empty surface of screen is filled with the continuous suspension liquid again and forms new filter cake.With the continuous reciprocating movement.,and the filter cake pulses forward and further drying.The filter cake goes into the secondary stage basket from the first stage basket,the filter cake is loose and redistributed on the secondary stage basket screen and pushed out of the basket,continuously go into the collecting tank 5,and finally the filter cake moves out of machine from the tangential discharge port by the scraper 4 installed in the secondary stage basket(if not using the scraper,the filter cake will directly drop into the machine casting and out of machine by gravity).The filter liquid phase and the wash water can be discharged by the liquid discharge port,if necessary,the filter liquid phase and the wash water can be discharged separately.

After the basket is rotating at full speed,the suspension liquid to be separated is fed into the feeding pipe 1 and continuously sent to the distributor 2.Under the action of centrifugal force,the suspension liquid evenly distributed on the first stage basket screen 3,and most.of liquid phase goes through out the screen mesh and the hole of basket,while the solid phase in the form of annular filter cake stays on the screen,when the first stage basket returns and pushes the filter cake moving forward a distance along the basket axial,and when the first stage basket process,the empty surface of screen is filled with the continuous suspension liquid again and forms new filter cake.With the continuous reciprocating movement.,and the filter cake pulses forward and further drying.The filter cake goes into the secondary stage basket from the first stage basket,the filter cake is loose and redistributed on the secondary stage basket screen and pushed out of the basket,continuously go into the collecting tank 5,and finally the filter cake moves out of machine from the tangential discharge port by the scraper 4 installed in the secondary stage basket(if not using the scraper,the filter cake will directly drop into the machine casting and out of machine by gravity).The filter liquid phase and the wash water can be discharged by the liquid discharge port,if necessary,the filter liquid phase and the wash water can be discharged separately.

The rotation of the basket is driven by the motor through v belt,the reciprocating movement of the first stage basket is driven by hydraulic system made by the composite oil cylinder.

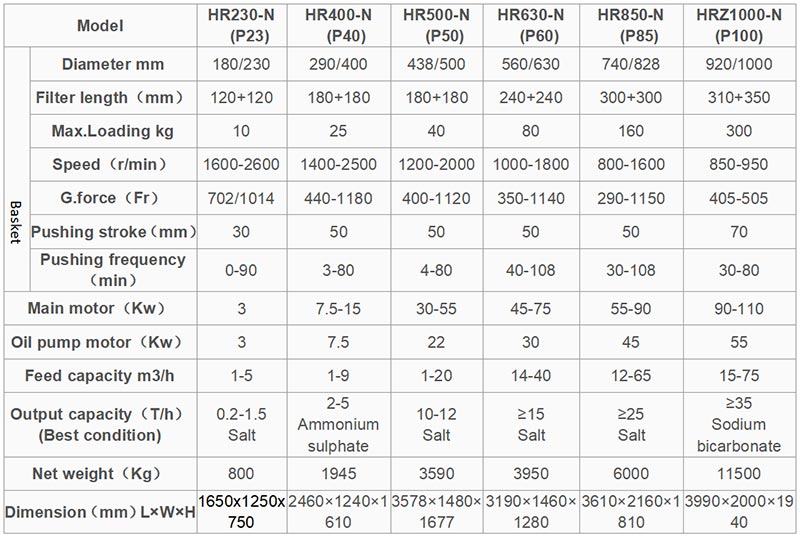

Technical Parameters