- Consulting:+86 131 7042 6166

- Mobile

- WeChat

- CN

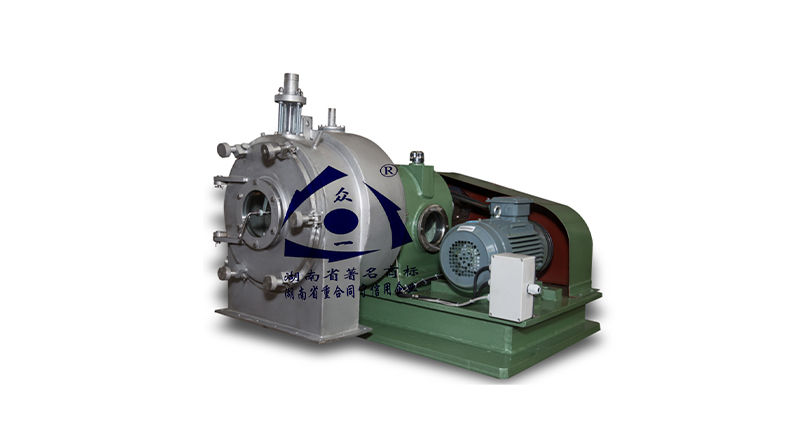

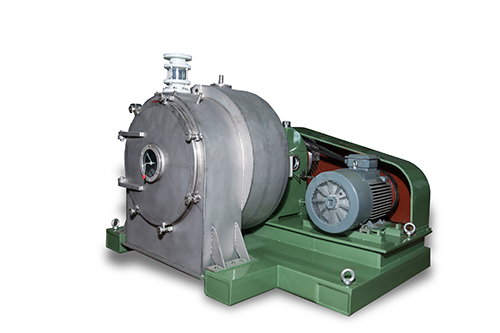

LLW(LWL)

Horizontal Screen bowl Scrolling Centrifuge

Product introduction

LLW(LWL)series centrifuge is a horizontal screw discharge and continuous operation filtering centrifuge.Capable of continuous feeding,separation,washing and unloading at full speed.

LLW(LWL)series centrifuge is a horizontal screw discharge and continuous operation filtering centrifuge.Capable of continuous feeding,separation,washing and unloading at full speed.

Application

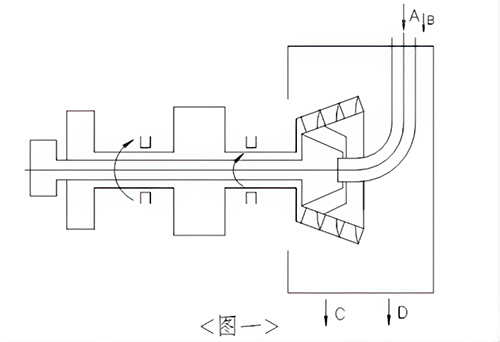

Mainly used for the separation and dehydration of liquid-solid two-phase suspensions with solid particle size of 0.05-10mm.It is used in chemical industry food chemical fiber mining metallurgy pharmacy light industry and other industries. The motor drives the basket and the concentrically mounted feeding screw to rotate at a certain differential speed in the same direction at a high speed.The materials are continuously introduced from the feed pipe and evenly distributed on the filter screen wall at the bottom of the basket.Under the centrifugal force,the liquid substances pass through the filter screen and the filter holes on the basket wall and are discharged from the drum,and are discharged out of the machine through the liquid outlet.The solid phase is trapped in the basket to form filter residue.Under the combined action of the conical component of centrifugal force and the feeding screw,the filter residue continuously moves towards the big end of the basket and is discharged out of the basket through the discharge chute.

The motor drives the basket and the concentrically mounted feeding screw to rotate at a certain differential speed in the same direction at a high speed.The materials are continuously introduced from the feed pipe and evenly distributed on the filter screen wall at the bottom of the basket.Under the centrifugal force,the liquid substances pass through the filter screen and the filter holes on the basket wall and are discharged from the drum,and are discharged out of the machine through the liquid outlet.The solid phase is trapped in the basket to form filter residue.Under the combined action of the conical component of centrifugal force and the feeding screw,the filter residue continuously moves towards the big end of the basket and is discharged out of the basket through the discharge chute.

Structure

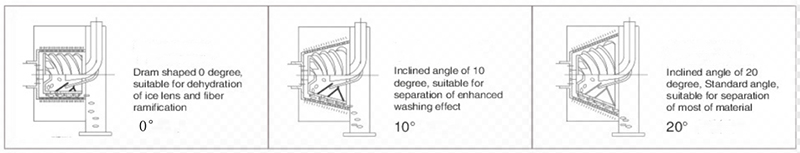

Screw parts can be specially designed

Screw can be bucket or cone shaped.Discharging speed and the time of filter cake staying on screen mesh are predetermined spiral can be of different angles for determining different discharging speed and time of filter cake staying on screen mesh,which is in accordance with customer's process requirements.

Following allocation can be possible to meet customers'demand.

1.Frequency conversion plus PLC controlling system.

2.Protection system for vibration and temperature rising.

3.Feeding speed control.

4.Gas-liquid separation device in liquid outlet.

5.Austenitic stainless steel(321/316L...),Hastelloy,titanium alloy or other corrosion resistant Contacting materials can be selected as the construction material of the centrifugeaccording to the requirements of the user.

6.Special configuration