XJZ

Top-suspended Automatic Scraper Discharge Centrifuge

Product introduction

Centrifuge XJZ is kind of fully automatic centrifuge with top suspended mechanical scraper discharge.It is used to separate sugar and honey under the action of centrifugal force field,and the sugar material is scraped off the drum wall through the radial and axial movements of the scraper to complete the unloading process.The machine is equipped with water washing and steam washing devices,which can fully wash materials.

Application

1.The machine is equipped with water washing and steam washing devices,which can fully wash materials and meet the needs of sugar production process.

2.This machine is widely used for separating honey from glucose paste and is a key equipment in the glucose industry.

3.This machine can also be used to separate materials with fine solid grains,high viscosity,good fluidity,tight texture and difficult to discharge by gravity.Generally,the solid-liquid ratio(weight ratio)of suspension is 40~60%.

4.The machine has good performance and the following features:

⑴AC variable frequency drive is adopted.In the periodic automatic cycle operation,the variable frequency stepless speed regulation can meet the requirements of low speed feeding,high speed separation,low speed unloading,etc.to the maximum extent.According to the change of material performance,the corresponding rotating speed point can be provided to achieve optimal operation.

⑵Programmable logic controller(PLC)is used for electrical control.The 10 inch color touch screen can set the time of each process and display the real-time working status of each process.It is flexible,simple and convenient to operate.

The whole machine is jointly controlled by electrical,pneumatic and mechanical equipment to realize full automatic cycle operation of each process.

(3)The parts in contact with materials shall be made of austenitic stainless steel,so as to ensure the cleanness of sugar and paste separation.

The overall structure is compact and the operation is stable.

⑷Large capacity,high speed,high separation efficiency,large production capacity,high degree of automation,low noise,and low labor intensity.

Working principle

When the basket rotates at a high speed,it will generate a centrifugal force that is thousands of times greater than its own weight,which will make the sugar paste on the wall subject to centrifugal force,and the granulated sugar grains will be trapped in the basket by the screen,forming a filter layer.Under the action of centrifugal force,sugar paste will pass through the filter layer and screen,and finally flow out of the basket hole wall to complete the separation of crystals and mother liquor.

The first sugar paste separation can be divided into four stages,namely,loading filter layer formation stage,centrifugal honey discharge stage,honey washing stage and drying stage.

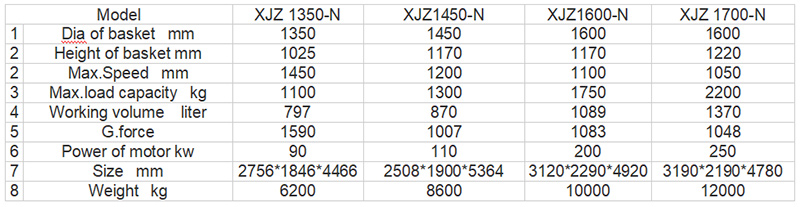

Technical Parameters